Life Cycle Assessment (LCA) of Cross-Laminated Timber (CLT) Produced in Western Washington: The Role of Logistics and Wood Species Mix

Summary

The use of cross-laminated timber (CLT) as an environmentally sustainable building material has generated significant interest within the wood products industry, architects and policy makers. The environmental impacts of CLT panels can vary significantly depending on material logistics and wood species mix. This study developed a regionally specific cradle-to-gate life cycle assessment of CLT produced in western Washington. Specifically, this study focused on transportation logistics, mill location, and relevant wood species mixes to provide a comparative analysis for CLT produced in the region. Five sawmills (potential lamstock suppliers) in western Washington were selected along with two hypothetical CLT mills. The results show that the location of lumber suppliers in reference to the CLT manufacturing facilities and the wood species mix are important factors in determining the total environmental impacts of the CLT production. Additionally, changing wood species used for lumber from a heavier species such as Douglas-fir to a lighter species such as Sitka spruce could generate significant reduction in the global warming potential (GWP) of CLT. Given the size and location of the CLT manufacturing facilities, the mills can achieve up to 14% reduction in the overall GWP of the CLT panels by sourcing the lumber locally and using lighter wood species. Introduction The supply chain for wood products is composed of a network of forest activities, harvest, processing, and distribution, and each stage within the supply chain can contribute to the total environmental impact. Transportation throughout the supply chain is an important factor that can have widely different impacts depending on the geographical features of the harvest locations and other operational factors. Specifically, the objectives of this study were: (a) to assess the environmental impacts of producing CLT panels in western Washington; and (b) to compare environmental impacts based on different logistics and wood species mix. Hence, this study developed a cradle-to-gate LCA based on existing literature and primary data. Several scenarios with different transportation distances and wood mixes were considered. The study compared the changes in impacts when different parameters were used.

Methods

This study used an LCA approach based on the ISO 14040 and ISO 14044 standards. LCA is a tool for evaluating the environmental impacts of a product throughout its entire life cycle, including raw material extraction, manufacturing and processing, usage, and disposal. The environmental impacts of a production or service system are evaluated based on the inputs and outputs of material and energy occurred at each life cycle stage for a defined functional unit of product. The material estimates used in this study were drawn from the Techno-Economic Analysis (TEA) for manufacturing cross-laminated lumber, which was undertaken with reference to manufacturing CLT in the Pacific Northwest (PNW), including resin type, resin volume, and energy at various stages of the manufacturing process. Data for processes such as electricity generation, lumber production, and fuel consumption were obtained from the U.S. Life Cycle Inventory database (USLCI). Inventory data for resin production came from a combination of LCI databases and existing literature. A CLT mill with a manufacturing capacity of 52,283 cubic meters per year was considered. SimaPro 8 was used to perform the LCA analysis.

The products and processes factored-in within this LCA analysis included forestry activities, material extraction, manufacturing, transportation, and CLT panels delivered at the building construction site. There were three main stages within the system: forestry activities and resource extraction, lumber production, and CLT production. Impacts associated with building construction, building usage, demolition, and end-of-life were not included in this study, nor were processes such as the manufacturing of capital equipment, facility maintenance, and labor costs. To compare the impacts associated with transportation logistics, five sawmills in western Washington were selected based on various factors including size, location, capacity, etc. The selected sawmills included Sierra Pacific mills in Aberdeen and Burlington, the Hampton mill in Darrington, Interfor in Port Angeles, and Weyerhaeuser in Raymond. Two potential CLT mills were hypothetically located near the cities of Forks and Darrington.

Results

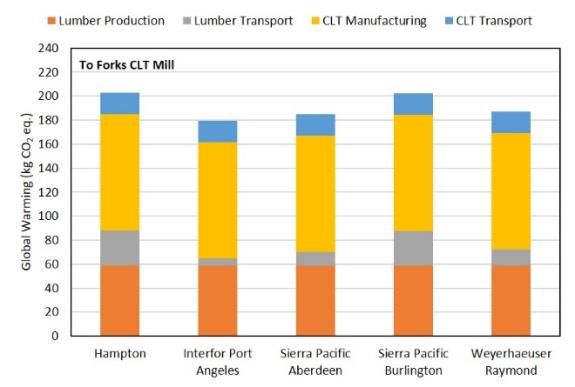

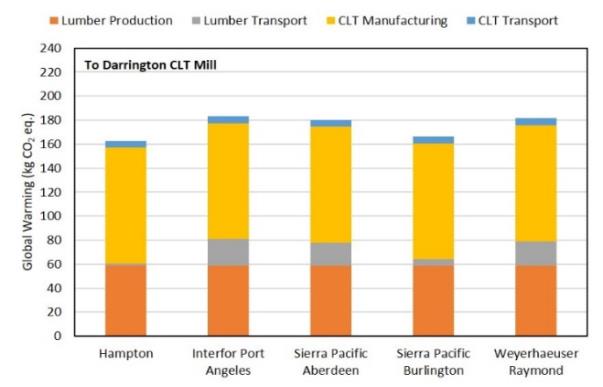

The overall environmental impacts from CLT manufacturing include impacts from forestry operations, lumber production, resin production, transportations, and on-site manufacturing.

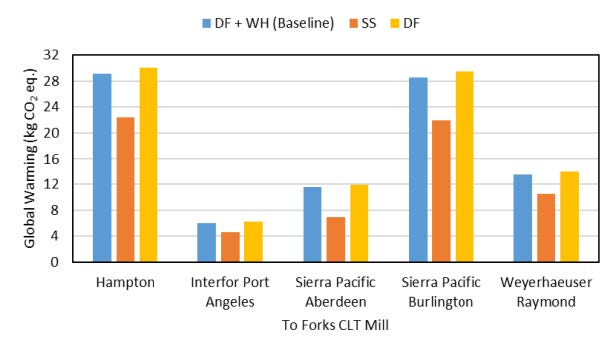

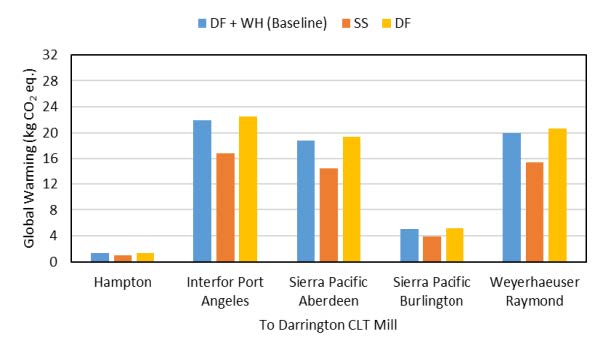

The location of production sites plays an important role in the total impacts. The addition of adhesives is also an important factor to consider. Considering GWP, keeping all other processes constant, different contributions from lumber transportation are shown in Figures 1 and 2.

A sensitivity analysis was performed to determine the changes in total impacts when different wood mixes are used. Figures 3 and 4 (next page) show the differences in GWP from transporting lumber made from a Douglas-fir and western hemlock mix (baseline case), Douglas-fir only, and Sitka spruce only. Because Sitka spruce is noticeably lighter than Douglas-fir and western hemlock, there is a clear declining trend in GWP under all transportation cases.

Although both lumber production and CLT manufacturing contribute significantly to the total impacts of CLT, changing the manufacturing process in an attempt to reduce environmental impacts is technically challenging and may require significant capital investment. Conversely, changing the sourcing and type of lamstock is a practical solution that can reduce the overall environmental impacts. The impacts of transportation strongly depend on the distance and road conditions. If performance specifications can be met, using lighter timber like Sitka Spruce rather than denser Douglas Fir can offsets some of the impact created by longer transportation distances. CLT manufacturing facilities can achieve up to 14% reduction in the overall global warming potential of the CLT panels by sourcing the lumber locally and using lighter wood species. Non-wood materials also can be influential in the overall environmental impact assessment. We found that resin contributes up to 30% of the overall CLT production GWP impacts and 15–19% of the overall CLT panel GWP impact. Improving the efficiency of resin production and its use in CLT will be a key step in limiting the environmental impact of CLT production.